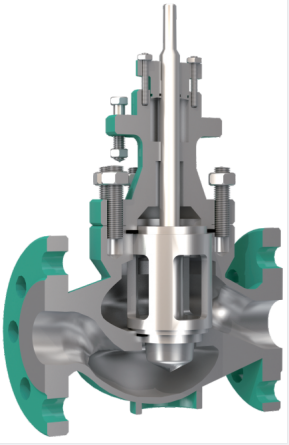

Model: XF61,XF62

Structure: Globe control valve, sliding stem

Size: DN15~DN250

Rating: PN16~PN63 (CL150~CL600)

Body: WCB, CF8, CF8M, CF3,CF3M

Trim: 304SS, 316SS, 316LSS

Actuator: Multi-spring pneumatic diaphragm

Accessries: Positioner, air fliter. etc

Sliding stem globe control valve

Overview of Sliding stem globe control valve

Sliding stem globe control valve is an important executive unit instrument in industrial automation process control. The flow characteristics of the regulating valve include: linear characteristics, equal percentage characteristics and parabolic characteristics. The most suitable installation of the Sliding stem globe control valve is that the upper end of the working piston is at the lower part of the horizontal pipeline. Its structure is composed of the actuator and the regulating valve, which is mechanically connected, assembled, debugged and installed to form the regulating valve.

Partial faults of Sliding stem globe control valve and solutions:

Fault 1: the actuator does not act, but the power supply and signal lamp of the control module are on.

Fault 2: the actuator does not act, the power light is on and the signal light is not on.

Fault 3: actuator vibrates and sounds.

Fault 4: the actuator does not operate normally, but the motor does not stop after the limit switch acts.

Fault 5: the actuator belt is broken.

1. Check whether the power supply voltage is correct; Whether the motor is disconnected; Whether the ten core plug is disconnected from the end to each wire terminal; Whether the plugs of motor, potentiometer and capacitor are in good condition; Judge whether the control module is in good condition by comparison and exchange method.

2. Check whether the polarity of input signal is correct; Judge whether the control module is in good condition by comparison and exchange method.

3. It is mainly because the sensitivity is adjusted too high, the insensitive area is too small and too sensitive, resulting in the instability of the small circuit of the actuator and oscillation. The sensitivity potentiometer is adjusted counterclockwise to reduce the sensitivity; The fluid pressure changes too much and the thrust of the actuator is insufficient; When the control valve is large, the valve often works at a small opening.

4. Check whether the limit switch and limit switch wiring are faulty; Replace the control module.

5. Check whether the internal transmission part of the actuator is damaged or stuck; Whether the "zero position" and "stroke" potentiometers are adjusted correctly; Check whether the limit switch is correct.

Note: Any special design or question of Globe type flow control valve, kindly contact the manufacturer for more details.

Contact: Kevin Zhang

Phone: +8615189522935

E-mail: sales@xfmeter.com

Whatsapp:+8615189522935

Add: No.286, Tongtai Road, Jinhu Economic Development Zone, Huaian, Jiangsu Province

We chat